Rotaprint is considered the inventor of small-format offset printing in Europe. But let’s start with the its history: it was founded in 1904 in Berlin as Deutsche Maschinen Vertriebsgesellschaft, a company that produced liquid toner copiers. From as early as 1906 its portfolio included a liquid toner copier called ‘Victoria’, which not only operated manually but was also available with an electric drive. At that time, a total of 20 employees worked in production and sales. In 1909, the production of the Victoria model was increased to 700 per annum and the number of employees doubled.

Shortly before the outbreak of the First World War, the Deutsche Maschinen Vertriebsgesellschaft employed 120 people and manufactured several models of hand- and electronically operated copying machines. After the war, the old production site in Sophienstraße was abandoned in favour of a larger site in Reinickendorfer Straße 46 in the Wedding neighbourhood. The company’s motto translated to: ‘And if they had gold instead of iron to offer: what use is it if nobody knows!’ 1 In 1922, and in this spirit, it launched a comprehensive advertising campaign to establish itself as a manufacturer of office machines.

The Rotaprint, the first-ever Office Offset machine in Europe, was presented to the public at the IBA – the International Office Exhibition (der internationale Büroausstellung) – in 1925.

In April of the same year, the development of the first Office Offset machine commenced. 2 ‘The first Rotaprint was a manually operated offset duplicating machine that printed from a paper roll and simultaneously cut it to the desired format.’ 3 The company’s greatest achievement with this machine was the successful transfer of the offset printing process to a smaller format. 4 It is worth noting that at the time, offset printing was still uncommon in Germany and other countries – with the exception of the US – and letterpress was the predominant process used by the printing industry.

With Rotaprint, Deutsche Maschinen Vertriebsgesellschaft developed not only an offset printing machine, but also the first Office Offset machine in Europe. This opened up completely new possibilities for reproduction. The market, which was inundated by spirit duplicators and mimeographs, suddenly had serious competition. In 1925, after a three-year development phase, the Rotaprint, whose manual operation has since been replaced by an electric drive, was presented to the public at the IBA – the International Office Exhibition (der internationale Büroausstellung) – in 1925. ‘As a congratulatory gesture, the business community provided an echo that had never been thought possible – in short, the Rotaprint machine became the sensation of the exhibition.’ 5 This was also the occasion for the company to change its name to Rotaprint.

This advertisement shows the many possibilities in which the printing plate (Rotaprint-Metallblatt) could be imprinted. This was a massive advantage compared to other duplication processes: ‘You write, draw or print on the Rotaprint metal sheet as if it were a piece of paper … and get up to 6,000 prints in an hour with the layman’s new multiplying and printing electric offset machine; the Rotaprint.’

There were two problems with the company’s product: its high acquisition costs, and the fact that, like the Victoria model, it printed from paper rolls. Increasingly, the market was demanding a single-sheet feeder and delivery section. Therefore, in 1927 Rotaprint developed the model Rkl, marketed as a ‘low-cost batch printer equipped with an automatic ink tray as an optional extra’. 6 The company developed rapidly in the 1930s, and factories opened across Germany. This development coincided with the start of the Second World War in 1939, but unlike Geha, which had to temporarily shift to arms production, Rotaprint continued to manufacture small offset and Office Offset machines, since the majority of the front’s printing plants were equipped with the company’s machines.

After the end of the war in 1945, however, Rotaprint experienced a high level of destruction – 75 per cent of the company was burned, and most of the remaining machines were buried under rubble. A move was considered and the company started making household items. But Rotaprint director Paul A Glatz continued to rely on the Berlin site, despite its isolated location. His instinct proved right, because by 1954 Rotaprint had bounced back, employing 495 people. From then on, the company focused more on the development and production of new and innovative small offset presses.

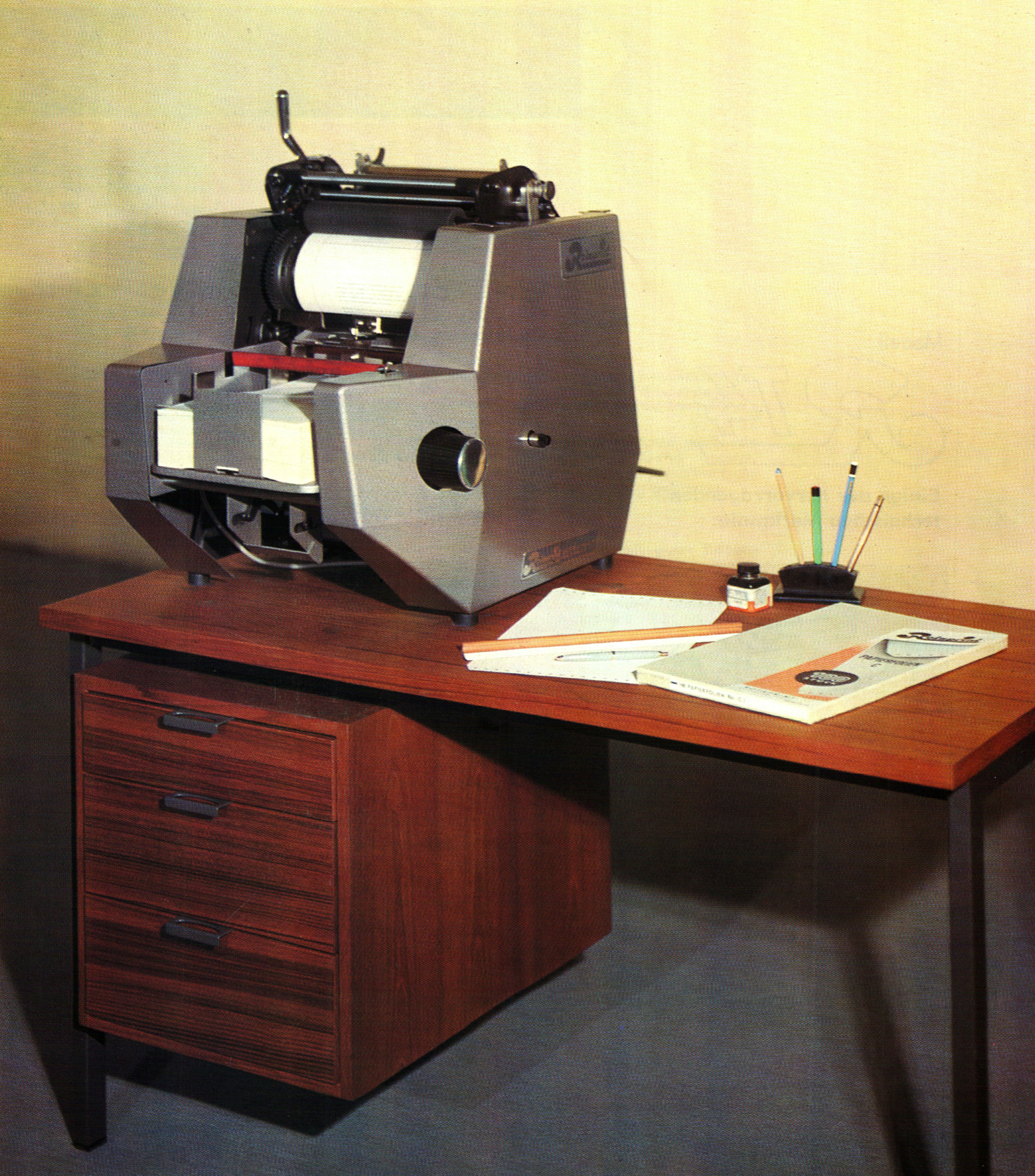

In 1951, the Rkl model became the Rotaprint R 40, which, with its suction feeder, was no longer purely a duplicating machine – and soon smaller offset printing companies became Rotoprint customers. In the 50s and 60s, more than 1,000 employees produced mainly for export – a full 60 per cent of production was sent abroad – and Rotaprint experienced an upswing that was exemplary of the economic miracle in Germany following the Second World War. 7 But it was not until 1967 that Rotaprint introduced a new Office Offset machine, the RT4 table-top model.

‘Model RT4 (table-top model) offset printing and duplicating machine, formats DIN A6 to DIN A4, electric drive, automatic counter, automatic inking unit, hydro-colour unit, printing capacity up to 6,000 sheets per hour, duck button switching, inking button, print image adjustment (horizontal and vertical fine adjustment while the machine is running, without blanket washing), modern sound-absorbing plastic casing DM 5.615 (£ 505).’ 8

An early example for an experimental use of the Office Offset is Wolfgang Fietkau’s small publishing house, where poems, experimental literature and concrete poetry were published. What is particular interesting, is his series, ‘schritte’. In 1970 Fietkau purchased a Rotaprint RT4 and a few machines for perfect binding and started to produce the series in his own printing workshop. Each 36-page book presented one author. Sized at 16 × 14 cm, the volumes were printed with tinted flying paper.

Garbe, Burckhard. Ansichtssachen, schritte 24, 1. Aufl. Fietkau Verlag

In the postwar years Rotaprint was at the helm of a printing revolution, which resulted in numerous copy-cats. Yet there was still more innovation to come. In 1972 the company developed the Offsetta and the RTS, succeeding once again in creating a small sensation. 9 An Office Offset machine that could handle up to 15,000 prints per hour was not yet available on the market. The machine justifiably received the iF Design Award for the best product in the communication segment in 1974. 10 Soon after, the Offsetta was developed into the Offsetta-Duo, which could print the front and reverse sides of sheets in one pass. A running capacity of 15,000 sheets allowed for 30,000 prints per hour. 11 In 1976, the consumer would have paid DM 9.975 (£ 2,196) for the Offsetta and DM 28.500 (£ 6,078) for the Offsetta Duo. 12

‘Rotaprint’s Offsetta, an automatic Office Offset machine, does not work with the usual rubber blanket, but with the so-called Offsettablatt, which makes the washing process unnecessary. But that’s not all: the press can handle 15,000 prints per hour with extremely quiet operation. And: a new type of suction-roller feeder removes the sheet from the underside of the paper pile. The pile can thus be replenished while the machine is running. Operation: Clamp the Offsettablatt and printing foil, preselect the print run, press the start button. That’s all.’ 13

The RTS and, later, the RTE/RTA were designed less for speed and mass reproduction, but rather for higher quality office printing products. The RTE/RTA model differed only in the number of ink form rollers and the total number of inking rollers in the inking unit. The RTE model had more rollers than the RTA model, which resulted in finer ink distribution and therefore cleaner printing. In 1976, the RTE cost DM 10.175 (£ 2,240) and the smaller RTA model DM 8.975 (£ 1,975). 14

‘The operating costs for Office Offset are known to be low. The production of half a dozen prints already justifies the use of this machine. Of course: the larger the print run, the smaller the unit price. The RTS can be used for a wide range of jobs: from simple office duplication to printed matter, which are normally produced on a larger machine. All-important printing processes are controlled with a single lever. Up to 120 prints per minute. The RTS only requires an area of 70 × 100 cm on any suitable table. Perfectly shaped: Not only does it look great – it also does something special.’ 15

At the beginning of 1980, the increasing price reduction and better quality of copiers across the market created tough competition for Rotaprint. As a result, the company ceased production of the RTS, RTE and RTA in 1981, citing an outdated machine concept that no longer met market requirements. 16 The company continued to remain active on the market by marketing the efficiency and speed of its machines. A further advantage of Rotaprint over its competitors was that its real mainstay, small-format offset printing, meant that the company did not produce exclusively for the office industry. With the reworked Offsetta II, Offsetta-Duo II and the new SPrinter model, Rotaprint succeeded in holding its own on the duplicating market alongside Xerox copiers.

‘The question of “copy or duplicate” has become more open than ever with the new Offsetta II. The fastest office printing system – 15,000 prints per hour or 250 prints per minute – has “uncopyable” office features…Already from six prints the Offsetta II can work more cost-saving than a copier. In comparison: material costs for 100 offset prints are only 37 pennies … The Offsetta Duo II offers double the printing performance by printing the front and back side simultaneously.’ 17

Speed and efficiency became the driving force at Rotaprint. With the SPrinter they raised the bar in the high-performance duplication segment. The degree of automation and printing performance made this model a unique machine:

‘The Rotaprint SPrinter is a high-performance duplicator that works on the offset principle. All operations, such as foil feeding, fixing, inking, printing and foil ejection, run automatically according to a specific program, without manual intervention by the operator. The most outstanding feature of the SPrinter is its extremely high printing speed. It can print up to 25,000 prints per hour, or just under seven prints per second, on all common paper qualities from 40–200 gsm.’ 18

‘There is currently no sheet-fed press of comparable size that even comes close to this speed. “Normal” offset duplicators can generally handle up to 7,000, possibly 8,000, only a few 10,000 sheets per hour in A4 format. High-performance printing presses in the professional sector achieve a maximum of up to 15,000 sheets per hour. For copy or large copy systems, the upper limit is approximately 9,000 copies per hour. An essential feature for the SPrinter in this context is that the speeds specified do not only refer to top-quality paper with optimum running characteristics, but also, for example, to recycled paper or thin paper. Even with these thin printing papers, the speeds mentioned are achieved up to about 75 to 80 per cent.’ 19

The SPrinter was capable of unbelievable 25,000 prints per hour, or just under seven prints per second.

Thanks to these new developments and steady business with small offset printing presses, in the early 1980s Rotaprint was showing solid sales figures and was able to hire more workers:

‘Rotaprint achieved sales successes for domestic and foreign markets at the Drupa 1982 in Düsseldorf with the launch of the new R 37 K and SPrinter models and other well-known models. The high demand since June 1982 has required the Berlin-based company to increase its production capacity (including a second shift in the production area) and, as a result, to expand its workforce by more than 20 per cent.’ 20

But the upswing was short-lived. In 1985, Rotaprint took over its competitor Roto-Werke and Roto International GmbH, with production continuing under the name Roto/Rotaprint. However, bad investments and poor management led to a drop in turnover at the Berlin headquarters, from 130 million marks (£ 31.5 million) in 1980 to 80 million marks (£ 20.4 million) in 1985. 21 The company tried everything to stop the downward trend. The SPrinter model was still the fastest Office Offset machine in the world and was further developed into a Tandem SPrinter. Similar to the Offsetta Duo II, two printing machines were connected in series, making it possible to print front and back in one pass. In combination with a so-called sorter, which deposits the individual prints to separate trays, Roto/Rotaprint tried one last time to hold its own against the Xerox copier. 22

The Tandem SPrinter with attached sorter

But even with its innovations in the field of Office Offset machines, Roto/Rotaprint could no longer stop the triumphal march of the copiers. And so in 1989 one of the oldest printing machine companies in the world went bankrupt. Inventory was auctioned off. A different company, Rotaprint Service, purchased almost all spare parts from the inventory. Today it still functions as a repair service for Rotaprint small-format offset printing machines, and the product range of small-format offset printing machines for R 36 and R 45 continued to be produced for several years by the Berlin company Unigrafica. The Rotaprint factory premises fell to the district of Berlin-Wedding, which sold them to the ExRotaprint, an initiative started in 2007 to transform the premises into a place for commercial enterprises, artists and social institutions. 23

1. The motto in German: Und wenn sie Gold statt Eisen zu bieten hätten: was nütze es, wenn keiner es weiß; Jaster, Ernst. Von Gutenberg bis Rotaprint, Berlin, E. Jaster 1954, p. 68

2. Cf. Jaster, Ernst. Von Gutenberg bis Rotaprint, Berlin, E. Jaster 1954, p. 65–69

3. Jaster, Ernst. Von Gutenberg bis Rotaprint, Berlin, E. Jaster 1954, p. 69

4. Cf. Jaster, Ernst. Von Gutenberg bis Rotaprint, Berlin, E. Jaster 1954, p. 65–69

5. Jaster, Ernst. Von Gutenberg bis Rotaprint, Berlin, E. Jaster 1954, p. 71

6. ibid., p. 74

7. Cf. Jaster, Ernst. Von Gutenberg bis Rotaprint, Berlin, E. Jaster 1954, p. 74–82

8. Kopplow, Horst. Rotaprint VIP Seminar Transkript, (1985), p. 6

9. ibid., p. 9

10. Cf. www.exhibition.ifdesign.de

11. Cf. Rotaprint GmbH. Offsetta-Duo Presseinformation, p. 2

12. V.I.T. Vervielfältigungs- und Informations-Technik, no 7 (1976), p. 29

13. BZB-Sachmagazin für Bürotechnik & EDV, no 5 (1976), p. 38

14. V.I.T. Vervielfältigungs- und Informations-Technik, no 7 (1976), p. 30

15. Cf. Rotaprint GmbH. Rotaprint RTS Prospekt: Ihre neue Arbeitskraft, p. 1

16. V.I.T. Vervielfältigungs- und Informations-Technik, no 4 (1985), p. 10

17. Büroausrüstung, no 4 (1980), p. 12

18. V.I.T. Vervielfältigungs- und Informations-Technik, no 1/2 (1985), p. 53

19. ibid., p. 22

20. ibid., p. 12

21. Cf. Hupe, Rainer. Riskantes Spiel um einen Konkurskandiaten. Die Zeit (08.08.1986)

22. Cf. V.I.T. Vervielfältigungs- und Informations-Technik, no 4 (1985), p. 10

23. Cf. www.exrotaprint.de

© Office Offset. All rights reserved. No part of this article may be reproduced or utilised in any form or by any means without the prior written permission of Office Offset.